Power Plant 1-3

What must be done to the connecting rods after a cylinder is removed?

They must be solvent washed and lubricated using fresh 10W30 oil

Nothing, they are just fine.

They must be supported using elastics or cardboard templates.

They must be lock-wired to the base studs to prevent movement.

What position is the piston supposed to be in when removing a cylinder from an engine?

TDC of the compression stroke

Any position

TDC on any stroke

. BDC of the exhaust stroke

When are the seals/packings on a cylinder replaced?

At annual inspections

At TBO

Every 500 hrs

Every time the cylinder is removed

What is ring stagger?

The spacing between the compression rings of a piston

The spreading out of the end gaps on the compression rings of a piston

When the rings don’t roll straight across the work bench

The waviness in the oil control ring

What needed to be done to get the piston into the cylinder when installing the cylinder on the Lycoming O235 engine?

Nothing, they slide in just fine

A ring compressor must be used

A pry-bar must be used

A hammer must be used to tap the cylinder down

What is the purpose of ring stagger?

To reduce leakage out of the combustion chamber

To prevent unwanted movement of the piston in the cylinder assembly

To scrape excess oil off the cylinder walls

To prevent sideways movement of the connecting rod on the crankshaft

What is used to seal the rocker covers to the cylinder head?

�OO” silk thread and sealant

RTV silicone

An o-ring

A cork gasket

What is used to seal the cylinder bases to the crankcase?

A silicone gasket

�00” silk thread sealant

An o-ring

A cork gasket

What needed to be done to get the piston into the cylinder when installing the cylinder on the Lycoming O235 engine?

A hammer must be used to tap the cylinder down

A pry-bar must be used

A ring compressor must be used

Nothing, they slide in just fine

How does oil get back to the crankcase from the cylinder head on the Lycoming O235 engine?

Through dedicated cylinder drain lines

Through the oil return manifold system and a scavenge pump

Through the pushrod shroud tubes

Through the pushrods

What tool is used to remove the Lycoming O235 cylinder base nuts?

Combination wrench

Vicegrips

A Ratchet & sockets

Ratchet & cylinder base nut wrench

When are the seals/packings on a cylinder replaced?

Every time the cylinder is removed

At TBO

Every 500 hrs

At annual inspections

What is the purpose of ring stagger?

To scrape excess oil off the cylinder walls

To prevent sideways movement of the connecting rod on the crankshaft

To reduce leakage out of the combustion chamber

To prevent unwanted movement of the piston in the cylinder assembly

What can cause low compression on a cylinder?

Compression rings, intake and exhaust valve seats, crack in the cylinder

Where are the seals/packings located on a cylinder?

Between cylinder head and rocker cover, between shroud tub I/O e and crankcase/cylinder head

What kinds of seals/packings are used on a cylinder (type, material, shape)?

Silicone gasket

When are the seals/packings on a cylinder replaced?

After every cylinder removal or on condition

What kinds of seals/packings are used on a cylinder (type, material, shape)?

Silicone gasket

When are the seals/packings on a cylinder replaced?

After every cylinder removal or on condition

How does the oil get from the cylinder head back to the crankcase?

Through the drain line (on lycoming engine)

Back through pushrods (on continental engine)

What adjustments are there on the cylinder? Why?

Valve Clearance, to ensure better compression

What must be done to the connecting rods immediately after cylinder removal?

Must be supported using elastics or cardboard template

What can happen if you do not support the connecting rod when the cylinder is removed?

Connecting rod can damage the crankcase or itself

Why do you “stagger the rings”?

To prevent airflow past the rings (not over the pin)

What tools did you need for this job?

Flathead screwdriver, torque wrench 300 inch pounds (25-35 ft. lbs.), cylinder base wrench, ratchet and sockets, valve adjustment tool, piston ring compressor

Where can leaks occur on a cylinder?

Around the intake/exhaust valves, piston’s oil rings, packings, seals, and any cracks in the cylinder case.

Where are seals/packings located on a cylinder?

Under the valve risers, cylinder flange, rocker box cover, and push rod shroud tube ends

What kinds of seals/packings are used on a cylinder (type, material, shape)?

Rocker box cover: Cork Cylinder base & push rod shrouds: Silicon Exhaust riser: Rubber Intake riser: Paper

When are seals/packings replaced?

Anytime the cylinder is disassembled and the seals are removed.

How does the oil get from the cylinder head back to the crankcase?

O200: Shroud tubes

O235: Oil drain tubes

What adjustments are there on a cylinder? Why?

O200: No valve adjustments thanks to its hydraulic lifters

O235: Adjust valve clearance with common screwdriver (necessary due to its solid lifters)

What must be done to the connecting rods immediately after cylinder removal?

Support the rods by securing them to the cylinder port to prevent them from scoring the crankcase.

Why would you “stagger the rings”?

It prevents compression loss due to warping of the rings.

What tools did you need to Re & Re the cylinder?

Cylinder base wrench, ring expander, screwdriver, ratchet, piston ring compressor.

When would you change a cylinder?

If the engine fails a differential compression test (low compression or cracked cylinder)

Obvious damage on cooling fins

Borescope finds corrosion

Cylinder is leaking

Cylinder doesn’t perform to specs

After extended time in storage

What is the torque for the cylinder base nuts?

3/8”: 300 in-lbs

7/16”: 420 in-lbs

What are the components of a cylinder assembly?

Cylinder head

Piston pin

Piston head

Valve Assembly

Piston rings

When are camshaft bearings replaced on the Lycoming O235 engine?

There are no camshaft bearings

How are the halves (outer halves on the O235 L2C) of a crankcase sealed?

By “00” silk thread and sealant

Why is it important to follow the correct torque pattern when reassembling a crankcase?

So the crankshaft is held and aligned properly in the case with its associated bearings

What lubrication methods are used for the camshaft journals?

Pressure

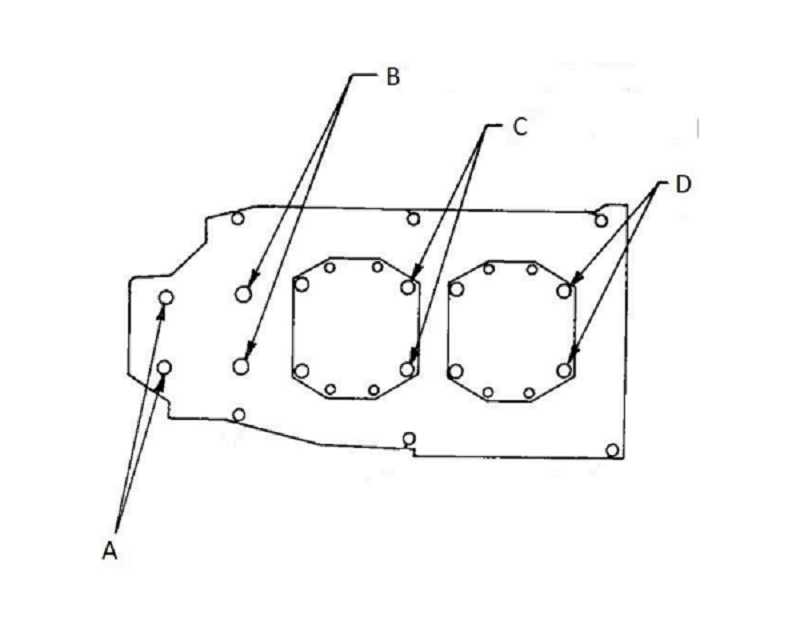

What is the correct torque pattern for the lycoming O235 case parting face bolt?

E,D,F,B,A,C

How are the halves of a crankcase aligned for assembly?

By dowel pins

When are camshaft bearings replaced on the Lycoming O235 engine?

Whenever the case is opened

When the camshaft is replaced, they are matched parts

Every 2000 hours of operation

There are no camshaft bearings

How is the accessory case aligned with the crankcase for assembly?

By the case bolts

By dowel pins

By the through bolts

By the crankshaft and camshaft

Why is it important to follow the correct torque pattern when reassembling a crankcase?

So the crankcase won't crack

So the camshaft bearings don't spin

So the Through bolts wont twist

So the crankshaft is held and aligned properly in the case with its associated bearings

What lubrication method is used for the camshaft lobes?

Immersion

Spray

Pressure

Splash

What is the correct torque pattern for the Lycoming O235 case through bolts?

B, A, D, C

C, D, B, A

A, B, C, D

C, D, A, B

Where can the crankcase leak?

Front and Back of the Crankcase, Rubber Sealings, Gaskets, Floating through Bolts.

How many through bolts hold cases together?

8

How often are the main bearings replaced?

Major Overhaul or Bulk Inspection (On condition)

Every 100 hours of operation

Once a year

When the engine reaches 10,000 hours of operation

How often are the camshaft bearings replaced?

There are no cam bearings.

Camshaft bearings are replaced every 10,000 miles

Camshaft bearings need to be replaced annually

Camshaft bearings typically last for 5 years before replacement

How is the crankshaft lubricated?

Pressure Lubrication

Splash Lubrication

Dry Lubrication

Air Lubrication

The crankshaft is lubricated by a network of tiny tubes

How are the camshaft journals lubricated?

Pressure Lubrication

Splash Lubrication

Dry Lubrication

Magnetic Lubrication

Air Lubrication

How are the camshaft lobes lubricated?

The camshaft lobes are lubricated via splash lubrication in the crank case

The camshaft lobes are lubricated by direct injection of oil

The camshaft lobes are lubricated by a pressurized air system

The camshaft lobes are lubricated by a magnetic field generated by the engine

The camshaft lobes are lubricated by a specialized gel coating

What is the torque pattern for torquing the crankcase through bolts?

1. Left side - middle 2. Left side - top 3. Left side - middle 4. Tightening right side - bottom case 5. Tightening crankcase fastening 6 to 13

3. Left side - middle 1. Left side - top 2. Left side - middle 5. Tightening right side - bottom case 4. Tightening crankcase fastening 6 to 13

2. Left side - middle 1. Left side - top 4. Left side - middle 5. Tightening right side - bottom case 3. Tightening crankcase fastening 6 to 13

Tightening crankshaft pulley

Torquing the oil pan bolts

What is the torque pattern for torqueing the crankcase parting face bolts?

0%

0

0%

0

0%

0

0%

0

0%

0

What size nuts are used for the cylinder bases?

9/16

5/8

1/2

3/4

7/16

What can cause damage inside the crankcase?

Over tightening of the through bolt causing damage to the journals/spun bearing.

Excessive heat buildup

Lack of lubrication

Foreign objects entering the crankcase

Corrosion or rusting of internal components

How are the crankcase assembly halved and sealed?

POB seals and Silk thread.

Bolted together with rubber gaskets

Welded together using high heat

Secured with adhesive tape

Joined with metal clips

How are the crankcase assembly halved aligned?

1st - right half and 2nd -left half (Via Dowel Pins)

Top half and bottom half (Via Dowel Pins)

Front half and back half (Via Dowel Pins)

Inner half and outer half (Via Dowel Pins)

Upper half and lower half (Via Dowel Pins)

When would you open the crankcase for inspection?

Only if the repair is needed or any damage is found

During routine maintenance

After every 100 hours of operation

When the engine is running smoothly

If there is a change in oil pressure

What tools were needed for this job?

Telescopic gauge, micrometer, feeler gauge.

Wrench

Screwdriver

Hammer

Pliers

What is clearance?

The space between two parts.

The amount of money needed to purchase an item

A type of sale or discount

A form of permission or authorization

The process of removing unwanted items or clutter

What is interference?

Lack of clearance/two parts touching.

Interference is when two objects merge together seamlessly.

Interference occurs when there is a lack of communication between two parties.

Interference refers to the disruption of a signal or transmission.

Interference is the result of external factors affecting the performance of a system.

What tool is used to measure inside diameter?

Telescopic gauge (measured at three spots).

Caliper

Micrometer

Depth gauge

Feeler gauge

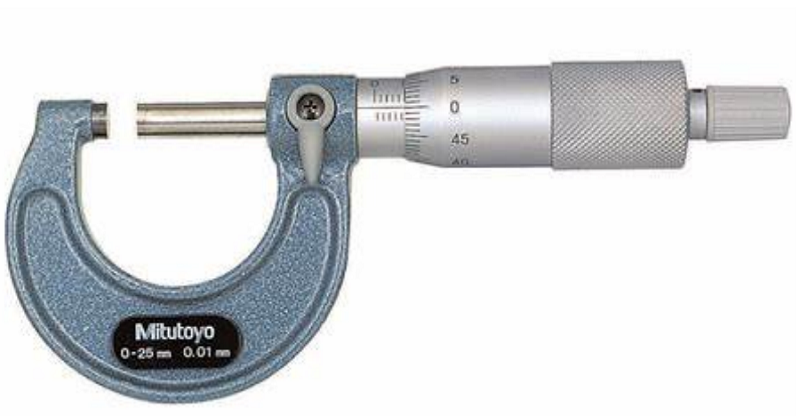

What tool is used to measure outside diameter?

Micrometer.

Caliper

Vernier gauge

Dial indicator

Gauge block

What tools are needed to measure a clearance?

Micrometer, bore gauge, feeler gauge, vernier calipers, etc.

Laser pointer

Thermometer

Screwdriver

Tape measure

How often will a micrometer be used for this kind of work?

All the damn time.

Rarely, only for special occasions

Occasionally, when other tools are not available

Never, micrometers are outdated and not used anymore

Only once in a blue moon, when precision is not important

How often will a vernier caliper be used for this kind of work?

Rarely, not as often a micrometer.

Only for very precise measurements

Occasionally, but not frequently

Only when measuring small objects

Not commonly used in modern industries

What is spark plug reach and how do you know what reach spark plug a cylinder requires?

The depth a spark plug threads in a cylinder. Thicker cylinder wall means more threads needed and therefore a longer reaching spark plug. .020 cylinders (yellow paint below spark plug) need longer reach.

Spark plug reach refers to the distance between the spark plug and the piston in a cylinder. It is determined by the size of the spark plug electrode.

The reach of a spark plug is the measurement of how far the spark plug protrudes into the combustion chamber. It is determined by the engine manufacturer's specifications.

Spark plug reach is the length of the metal shell of the spark plug. It is determined by the type of ignition system used in the vehicle.

The reach of a spark plug is determined by the compression ratio of the engine. Higher compression engines require longer reach spark plugs.

How do you know what treatment a cylinder wall has?

It’ll have painted fins below the spark plug (Lycoming)

The cylinder wall will have a rough texture

There will be visible scratches on the cylinder wall

The cylinder wall will have a glossy finish

There will be a distinct odor coming from the cylinder wall

When would you measure a cylinder?

During overhaul, bulk inspection, or repair.

During routine maintenance

When conducting a pressure test

After a cylinder has been painted

When checking for corrosion

How would you know if a cylinder is chrome plated?

Orange painted fins

The cylinder has a rough texture

The cylinder is magnetic

The cylinder has a strong odor

The cylinder reflects light differently

How would you know if a cylinder is nitrided?

Blue painted fins.

The cylinder has a rough texture

There are visible cracks on the surface of the cylinder

The cylinder emits a distinct odor when heated

The cylinder becomes magnetic after nitriding

How would you know if a cylinder is cermicrome plated?

Orange AND white painted fins.

The cylinder has a rough texture

The cylinder is magnetic

The cylinder has a strong odor

The cylinder is transparent

How would you know if a cylinder is .010” oversized?

Green marked.

The cylinder would have a noticeable increase in diameter.

There would be a slight decrease in the cylinder's internal volume.

The cylinder would have a smoother surface finish.

The piston would fit loosely inside the cylinder.

How would you know if a cylinder is .020” oversized?

Yellow marked.

The cylinder would have a noticeable increase in diameter

There would be a significant decrease in the piston clearance

The cylinder walls would show signs of excessive wear

The engine would produce more power due to increased compression

How often will the crankshaft bearings be removed?

At overhaul

Every 10,000 miles

Once a year

After 100 hours of operation

Only when there is visible damage

How often will the connecting rod bearings be removed?

At overhaul

Every 10,000 miles

Once a year

After 100 hours of operation

Only when there is visible damage

How often will the piston pin bushing be replaced?

On condition

Every 100,000 miles

Once every 5 years

Only when the engine is overheating

After every oil change

What is run out?

How far it rotates off the axis. Eccentricity/ like a skipping rope/ out centre.

It refers to the distance covered by a runner during a race.

Run out is a term used in cricket to describe when a batsman is dismissed by a fielder throwing the ball and hitting the stumps before the batsman reaches the crease.

Run out is a measurement of how much fuel is left in a vehicle's tank.

In gymnastics, run out refers to the distance a gymnast covers before executing a tumbling pass or vault.

What is a slinger flange?

A flange at the front end of the front journal which acts as an oil slinger. Helps to sling the oil back into the engine and there is a rubber seal

A slinger flange is a type of decorative accessory used in fashion design.

A slinger flange is a term used in the construction industry to describe a specialized tool for applying mortar.

A slinger flange is a slang term for a person who is skilled at throwing frisbees.

A slinger flange is a type of musical instrument commonly used in traditional folk music.

What kind of crankshaft was used in the O200 engine we inspected?

Nitrided. It can be re-grinded then a larger bearing insert can be used and then it has to be re-hardened.

The O200 engine we inspected used a forged steel crankshaft.

The crankshaft in the O200 engine we inspected was made of cast iron.

The O200 engine we inspected had a chrome-plated crankshaft.

The crankshaft in the O200 engine we inspected was made of aluminum.

What process is used to harden the O200 crankshaft?

Nitriding is a heat treating process that diffuses nitrogen into the surface of a metal to create a case-hardened surface.

Tempering is a process used to harden the O200 crankshaft.

Galvanizing is a process used to harden the O200 crankshaft.

Annealing is a process used to harden the O200 crankshaft.

Quenching is a process used to harden the O200 crankshaft.

Describe the type of bearing used in the connecting rod at the crankshaft end

2 piece, semicircular split style bearing

Ball bearing

Needle roller bearing

Tapered roller bearing

Thrust bearing

What keeps the connecting rod bottom bearings and the crankshaft bearings from turning?

Notches and tangs. The crushing weight of the case

Magnetic force

Friction

Gravity

Lubrication

How do you know which cylinder a connecting rod will be installed in?

The number is found on the cap of the connecting rod where it connects to the crankshaft, there are two numbers: 1 on the bottom part and the other on the rod, these numbers line up to close the connecting rod onto the crankshaft to correspond with the correct cylinder

The connecting rod is randomly assigned to a cylinder during assembly.

The cylinder number is determined by the size of the connecting rod.

The connecting rod is labeled with the cylinder number on the piston head.

The cylinder number is determined by the position of the connecting rod in the engine block.

What is the name of this tool, and what does it measure?

Dial Indication - Run out (face of flange, centre journal)

Telescoping Gauge/ snap gauge/transfer gauge - Inside diameter

Micrometer - Outside diameter

Feeler gauge - End Clearance (rod on crankpin)

Depth Gauge - Depth

What is the name of this tool, and what does it measure?

Dial Indication - Run out (face of flange, centre journal)

Telescoping Gauge/ snap gauge/transfer gauge - Inside diameter

Micrometer - Outside diameter

Feeler gauge - End Clearance (rod on crankpin)

Depth Gauge - Depth

What is the name of this tool, and what does it measure?

Dial Indication - Run out (face of flange, centre journal)

Telescoping Gauge/ snap gauge/transfer gauge - Inside diameter

Micrometer - Outside diameter

Feeler gauge - End Clearance (rod on crankpin)

Depth Gauge - Depth

What is the name of this tool, and what does it measure?

Dial Indication - Run out (face of flange, centre journal)

Telescoping Gauge/ snap gauge/transfer gauge - Inside diameter

Micrometer - Outside diameter

Feeler gauge - End Clearance (rod on crankpin)

Depth Gauge - Depth

What is the name of this tool, and what does it measure?

Dial Indication - Run out (face of flange, centre journal)

Telescoping Gauge/ snap gauge/transfer gauge - Inside diameter

Micrometer - Outside diameter

Feeler gauge - End Clearance (rod on crankpin)

Depth Gauge - Depth

{"name":"Power Plant 1-3", "url":"https://www.quiz-maker.com/QPREVIEW","txt":"What must be done to the connecting rods after a cylinder is removed?, What position is the piston supposed to be in when removing a cylinder from an engine?, When are the seals\/packings on a cylinder replaced?","img":"https://www.quiz-maker.com/3012/CDN/97-4789987/torque-pattern.png?sz=1200"}

More Quizzes

Movie round

12658

Who run the world? GIRLS.

10522

Metacognition

520

How to make money online

1050

Free Death of a Salesman

201025474

Think You Know Characteristics of Matter? Take the!

201027781

Free U.S. Government and Citizenship Knowledge

201026439

Free Perfect Competition: Spot the Exception

201021867

Free Project Management Staff Knowledge Test

201025945

Romeo Juliet Questions: Test Your Shakespeare IQ

201026189

Free Networking Fundamentals Chapter Assessment

201026695

Kesha IQ Test: Are You More Like Kesha or Taylor Swift?

201032211