Powerplant Finals

Why are there two valve springs per the intake and exhaust valve?

Only the intake has two springs

To get more sprig bounce

To Prevent valve float

Only the exhaust has to springs

How can intake leaks be found ?

Blowing smoke into the carb intake and looking for the smoke to leak…

Pressure testing with soap and water using shop vac designed for testing purpose

Using a vacuum tester

Pressure testing with suction and water using any shop vac available

Proj. 9 how will the full flow external oil filter on the lycoming engine be…..

By SOAP analysis

By sending it out to another company

By cutting it open and visual inspection

By magnetic particle inspection.

At what conditions would this oil be used

Summer time when its hot

Winter time when its cold

For engine break in

Any season

What design feature allows for varying rates of cylinder thermal expansion?

Size of valves

Brass valve guides

Cylinder choke

The size of the vase studs

Proj 7 if a continental fuel injection system is running rich at or near full… what needs to be adjusted?

Pump pressure relief valve

Low unmetered fuel pressure

The variable orifice

Idle mixture

Proj 7 what is the purpose of a case drain ?

To allow excess oil in the engine to be vented overboard

To return excess fuel from the FCU to the fuel pump

To return excess fuel from the fuel pump to the fuel tanks

To prevent fluids from mixing inside the engine

What is the purpose of the case drain on the engine driven fuel pump or continental fuel injection system?

To lubricate the pump shaft seal

To suck air into the pump

To drain the pump housing to check for water

To indicate if the pump has a leaking seal

What should be done to the aircraft before engine removal is started?

Lock the control locks

Close intake valves

Disconnect the ac battery for safety

Ground the ac battery for safety

How is an oil suction screen plug installed correctly?

Tighten until the gasket does not crush anymore

Tight then another 360 degrees

Torque to 17 ft pounds

Tighten until sealing are in contact the another 135 degrees

Proj. 8 what is the correct installation for the throttle control hardware?

0%

0

0%

0

0%

0

0%

0

What will be used to lubricate the oil filter seal before installation?

Clean engine oil

Nothing it comes pre- lubricated

Used engine oil

5606 hydraulic fluid

How are the halves of a crankcase sealed?

By 00” silk thread and sealant

By a cork gasket

By a silicone gasket

By a paper gasket

Why is gear backlash necessary?

Prevent gears from binding

To prevent contaminants from getting between the gears and causing wear

To provides space for a film of lubricating between the teeth

To provide space for a film of lubricating air between the teeth

Proj. 9 how many times can the suction screen gasket be used?

On condition when annealed

2 times when annealed

Once its a crush type gasket

3 times when annealed

What is an indication of an intake leak when visually inspecting spark plugs

The plug has black sooty residue

The plug has brown residue

The plug has white residue

The spark plugs show of the running condition of the engine

Proj 6. How do you know which cylinder a connecting rod will be used ….

The cylinder number will be stamped into the rod and cap bolt bosses

The cylinder number will be stamped into the rod small end

The cylinder number will be scribed onto the side of the rod.

The connecting rod can be used on any cylinder

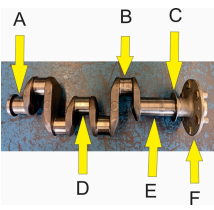

Proj 6 where is run out checked for on a crankshaft #1

On the crankpin

On the aft main journal

On the front main journal

On the centre main journal

Proj. 6 where is run out checked for on a crankshaft #2

On the front main journal

On the crankpin

On the propeller flange

On the aft main journal

Proj 6 how was run- out measured on the O-200 crankshaft?

With a vernier calliper

With a transfer gauge and micrometer

With a dial indicator

With a micrometer

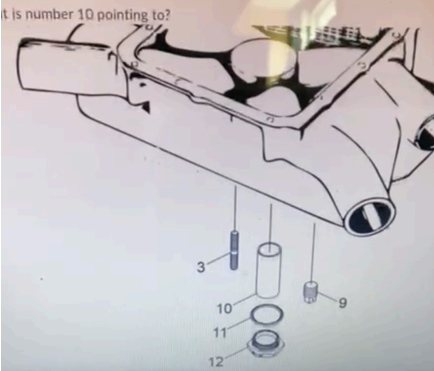

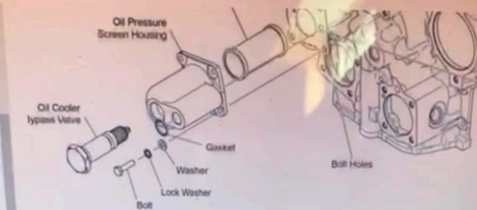

What is number 10 pointing to

Oil pressure screen

Oil pressure regulatory assy

Oil suction screen

Oil suction assembly

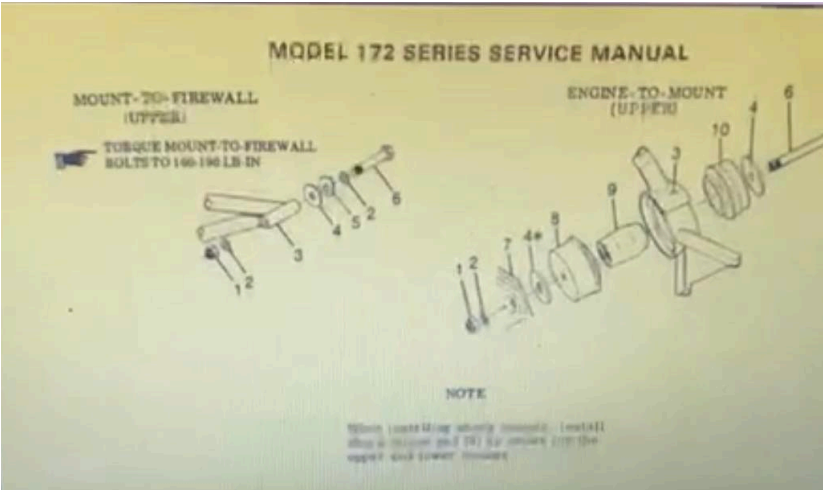

Proj 8 what is the correct torque for the 172 engine mount?

450-500 in lbs

160 - 190 ft lbs

160-190 in lbs

450- 500 ft lbs

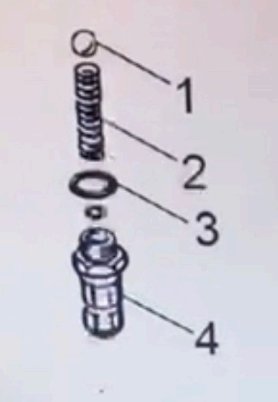

What is under this plug on O320H engine?

Oil suction screen

Oil pressure screen

Its just a plug

Oil pump adjustment

How does oil get from the cylinder head back down to the crankcase on the O200

Through the cylinder assembly

Through the oil drain lines

Through the push rod shroud tubes

Through the push rods

How would you know if a cylinder is nitrided?

It is a marked orange and white

It is marked orange

It is marked blue

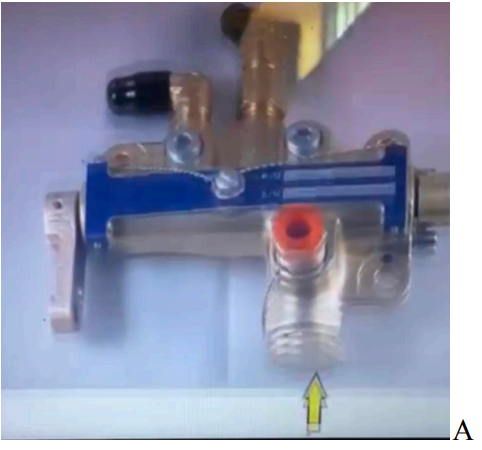

Proj 7 what adjustment is pointed to by A on this continental throttle body

Low unmetered fuel pressure

Idle speed

High metered fuel pressure

Idle mixture

Proj 7 what is the part pointed by A

Fuel filter

Fuel pump

Throttle body

Injector nozzle

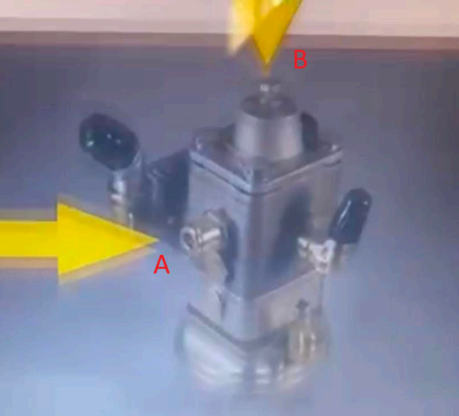

Proj 7 what adjustment is pointed to by B on this Continental fuel injection pump?

Idle speed

Idle mixture

High fuel pressure

Low fuel pressure

What type of fuel injection system is the continental?

Continuous flow

Direct injection

Throttle body fuel injection

High pressure fuel injection

How was the wear on the gears in the accessory gearbox measured?

Using the 2 pin technique and vernier calliper

Using feeler gauges

Using the 2 pin technique and a micrometer

Using the 2 pin technique and feeler gauges

On the O200 where does the oil after the oil pump

To the filter screen

To the LH main oil gallery

To the RH main oil gallery

To the pressure regulator

How often would you change the oil on this engine setup?

25hrs of air time

25hrs of flight time

50hrs of air time

50hrs of a flight time

Proj 8 which of the following tasks will require a dual inspection of the controls.

Adjustment of the idle mixture

Adjustment of the idle speed

Adjustment of the throttle cable length

Adjustment of the fuel pump pressure

If the valve clearance on an engine with hydraulics lifters is found to be large, what corrective action would you take?

Replace the push rod with a shorter one

Adjust the screw on the rocker arm clockwise

Heat up the push rod and stretch it

Replace the push rod with a longer one

What are the first steps one should take when troubleshooting a rough running injected engine?

Clean finger screen and fuel nozzles

Check torque on the fuel nozzles

Adjust idle speed

Make adjustments to the high and low pressure sides of the fuel pump.

Proj. 9 If shiny metal particles (non-magnetic) are found in the suction screen, where could they be from?

Camshaft lobes

Piston pin plug

Main bearing

Accessory gear bushings

When removing a cylinder what position should the piston pin be at?

Top dead center on the compression stroke

Any position

Bottom center on the power stroke

Top dead center on the exhaust stroke

What kinds of bearings are used in the engines we worked on in the lab?

Plain bearings, pressure lubricated

Plain bearings,splash lubricated

Roller bearing, pressure lubricated

Roller bearing splash lubricated

Proj. 6 what part of the crankshaft is pointed to by “C”?

Slinger ring

Rear main journal

Propeller flange

Crankpin

Proj 6 What is it called when the propeller flange "wobbles" as it turns?

Run-out

Crooked

Normal

Out of round

What are these parts called?

Crank front journal bearings

Thrust washers

Thrust wedges

Prop spacers

Proj.6 what part of the crankshaft is pointed to by "A"

Crankpin

Propeller flange

Slinger ring

Rear main journal

Proj. 1 what kind of tappets does the Lycoming O-235 engine have?

Solid tappets

Hydraulic lifters

Solenoid tappets

Hydraulic tappets

What was this tool used for?

Torque base nuts only

Torque through bolts only

Remove inter cylinder baffle

Remove and install cylinder base nuts

What does this bunch of parts do in the engine oil system?

Controls output pressure of the oil pump.

Controls flow of oil filter

Controls oil pressure to the suction screen

Oil cooler bypass valve

Proj 8 what needs to be done immediately after disconnecting fluid?

Disconnect all electrical wiring to the engine

They need to be cleaned and serviced

They should be removed and replaced

Cap and plug the lines and fittings

Proj 1 what must be done to the connecting rod after a cylinder is removed?

Nothing they are just fine

They must be lock-wired to the base studs to prevent movement

They must be solvent washed and lubricated using fresh 10W30 oil

They must be supported using elastics or cardboard templates

What would be an indication that an intake gasket is leaking?

Blue staining around the intake tube flange

Blue staining around the cylinder base seal

The grey paint on the intake tube is peeling

Blue streaks on the aircraft windshield

What kind of lifter would be used if this rocker was installed?

Hydraulic

Roller

Solid

Pneumatic

Project 8. How much bounce/cushion should there be in the 172 engine system according to the MM?

100 inch pounds of pressure

⅛ of an inch

� of an inch

One and a half inches

{"name":"Powerplant Finals", "url":"https://www.quiz-maker.com/QPREVIEW","txt":"Why are there two valve springs per the intake and exhaust valve?, How can intake leaks be found ?, Proj. 9 how will the full flow external oil filter on the lycoming engine be…..","img":"https://www.quiz-maker.com/3012/images/ogquiz.png"}

More Quizzes

IT HelpDesk_A+ Course Module 1 Quiz

15818

Nilkanth Charitra (Chapters 1-15)

452230

What is Your Patronus?

14713

Business studies Chapter 17

4227

Ultimate Cartoon Questions: Test Your Animation IQ

201073930

What Taylor Swift Song Are You? Free to Find Out

201030156

Are You Brave Enough for The Ghost of Fossil Glen?

201050064

Can You Master Hydrogen Atom Models? Take the!

201050064

Analog Clock: Master Time Reading in 10 Easy Questions

201026839

The Outsiders Chapter 4 - Do You Remember It All?

201053676

What Is Your Motto? Find Your Personal Life Motto Now

201027104

Administrative Law

15819883