Servicing Midterm

How are the calibrated tools in stores are maintained in a serviceable condition?

Stores is only there to issue and receive tools they are not involved in the calibration process.

The AME is responsible to track, record, repair and calibrate all precision calibrated tools.

Stores personnel are responsible to ensure the calibrated tools are sent for calibration prior to their expiration due date.

The calibration shop is responsible to track the tooling for your company, they are the ones who track, record and maintain the tooling.

Where would you find the PPE (personal protective equipment) requirements for using chemicals like, hydraulic fluid or acetone?

In the manufactures SDS for each chemical you are using.

Your supervisor will tell you what to wear to protect yourself.

PPE is not necessary to wear, so you can use your own discretion.

The chemicals used in aviation are not harmful, therefore you don't need to ever wear any PPE.

What is the difference between box 13 and box 14?

Box 13 is for AMO'S to certify the part and box 14 is for manufacturers of new aeronautical products

Box 13 is for manufacturers of new aeronautical products, block 14 is used by AMO'S to certify the part

Box 13 is the maintenance release for manufacturers of used aeronautical products and box 14 is for non aeronautical product certification

Box 13 is for the part description and box 14 is for the serial/batch number

What is block 8 on a form 1 used for?

This block is used to identify the part number.

This block describes what was done to the items described.

This block is used for the work order number, contract number or invoice

This block is used by AMO's to certify the work performed on the aeronautical product identified.

When placing chocks at an aircraft's wheels especially large transport category aircraft what is one of the cautions or considerations for the ground crew?

Make sure the chocks are as tight to the wheels as possible.

Make sure the chocks are set at a slight gap to the wheels as to allow for loading of the aircraft.

Make sure you chock one set of main wheels.

Make sure you use wooden chocks they it is the best material for chocks.

Can you use a fall protection harness and work at heights without being trained for fall protection?

Yes, you can wear a harness and work at heights without training for fall restraint only, not fall arrest.

No, there are specific training requirements that must be met prior to working at heights safely.

There is no training available for working at heights.

Yes its self explanatory and no training is required.

The risk diamond has 4 different colour squares, each square will have a number in it. What do the numbers represent?

The blue, red and yellow squares will have a number from 0 to 4. 4 being normal or low risk. 0 being dangerous or high risk. The white square will have letters or a symbol and a number to indicate the specific hazard.

It is up to us to determine the risk of the substance or chemical. The manufacture is not responsible to tell us what it is or how dangerous it is.

The blue, red and yellow squares will have a number from 0 to 4. 0 being normal or low risk. 4 being dangerous or high risk. The white square will have letters or a symbol to indicate the specific hazard.

The blue, red and yellow squares will have letters or a symbol to indicate the specific hazard. The white square will have a number to indicate the specific hazard. 0 being low risk and 4 being dangerous or high risk.

What goes into box 4 on a Form 1?

The name and address of the organization

The part number

The serial or batch number

The form tracking number

What level of government is responsible for occupational health & safety in aviation?

Aviation is Federally regulated.

Aviation is both Federally & Provincially regulated.

Aviation is Provincially regulated.

Occupational health & safety for aviation is not regulated.

What do you do with the form 1 document after you have installed the part on the airplane?

The form 1 becomes part of the aircraft technical records. It must be added to the technical logbooks for that aircraft.

You need to send it back to stores to have a new part ordered.

The AME must keep it in their own personal records.

You can discard it after the part has been installed.

Does a form 1 give the AME the authority to install a part on an airplane?

Yes, provided your director of maintenance agrees with you.

No, you need to verify the part in the IPC ( illustrated parts catalogue).

Yes, provided the airplane is a Canadian registered aircraft.

No, a form 1 is only used with an unserviceable part and you cannot install an unserviceable part on an airplane.

Are calibrated tools tracked?

No the AME is responsible for making sure the tool gets calibrated when it is expired.

Yes they have a special electronic tracking tag which alerts stores personnel when the tool needs to be calibrated.

Yes there has to be a method of recording the purchase and calibration of calibrated tools. Usually a logbook to keep track of the tool from purchase to removal from service.

As long as the tool has a serial number the AME is able to use it they do not need regular calibration it is only on an as needed basis.

Both the CRJ service door and the Citation main cabin door have a way of preventing the door from moving when it is fully opened. What is this commonly referred to as?

There is a cam and latch mechanism that locks the doors open and must be released prior to closing the door. It is commonly referred to as a gust lock.

The doors are held open by a counterbalance weight that is attached by ground crew personnel after opening the doors.

The weight of the doors themselves are what keep them open.

The doors are held in place by an over centre linkage.

Identify this WHMIS symbol

Corrosive material

Dangerously reactive material

Oxidizing material

Explosive material

What happens to a part or component if it is received by stores without a form 1 or identifying documentation?

The part must be issued to and installed on the aircraft it came off.

The part must go into bonded stores, we can consider it serviceable.

The part must go into quarantine stores until we can determine its serviceability.

The part must be shipped back to the repair facility immediately.

What is the purpose of the receiving and inspection area in stores?

The receiving and inspection area is just a bench for the shipping company to drop off the parts or hardware in stores, no further action is required with the parts or hardware.

So the stores personnel can certify the incoming parts by creating a form 1 for aeronautical products and batch numbers for non aircraft hardware.

So the stores personnel can verify the received parts are correct according to the invoice and have all the completed documentation.

So the stores personnel can pay for the incoming parts.

If the door handle is left unlatched on the CRJ main cabin door, would the pilots be aware of this prior to take off?

No, they rely on the ground crew to close and lock all doors properly prior to departure.

No, only the cargo door has an indication in the flight deck.

Yes, there would be a flight deck indication telling them there is a door open.

No, only the avionics bay door has an indication in the flight deck.

When you request a calibrated tool from stores, who is ultimately responsible to ensure the tool is serviceable?

The manufacturer is responsible to ensure the tool is serviceable.

The person receiving the tool for use.

Both, the person sending the tool for calibration and the person receiving the tool from the repair shop.

The person issuing the tool for use.

When opening an aircraft door, we need to be cautious of several factors. One of these factors is ensuring the emergency slide/raft is disarmed. Usually the slide/raft will be automatically disarmed when opening the door from, where the inside or outside?

Usually from the outside, however the Boeing 737 is one of the exceptions, it has a manual girt bar. The cabin or flight crew are the only ones who can safely disarm the emergency slide/raft.

When opening the door from the outside on all aircraft.

When opening the door from the inside on all aircraft.

Only the cabin or flight crew can safely open the door on any aircraft.

What is fall restraint?

A fall arrest system prevents workers from reaching a hazard, such as the edge of a roof.

�A fall restraint safety system keeps you from getting close enough to the fall hazard. Keeping you within a safe distance from the edge.

Fall restraint systems are not necessary for use in aviation

You do not need to be trained for fall restraint, however you do need to be trained for fall arrest.

For aircraft exterior cleaning there are three major methods. What are the three major methods?

Wet wash, air wash and vacuuming.

Steam blast, sand blast and glycol wash.

Wet wash, dry wash, and polishing.

Spot wash, spot polish and steam blasting.

Why do we tie down small aircraft?

Aircraft are only tied down for long term storage.

Aircraft are tied down after each flight to prevent people from stealing them.

Aircraft are tied down after each flight to prevent damage from the airport personnel forgetting to apply the parking brakes.

Aircraft are to be tied down after each flight to prevent damage from sudden storms.

What knot is commonly used to tie aircraft down?

Anti-slip knots, such as the bowline, are quickly tied and are easy to untie.

The granny knot, is the most common knot used to tie down an aircraft.

A tripod lashing knot, is the most common knot used to tie down an aircraft.

The icicle hitch knot, is the most common knot used to tie down an aircraft.

What hand signal is this?

Engine fire.

Proceed at your own discretion.

Brake fire.

Make a 180 degree turn.

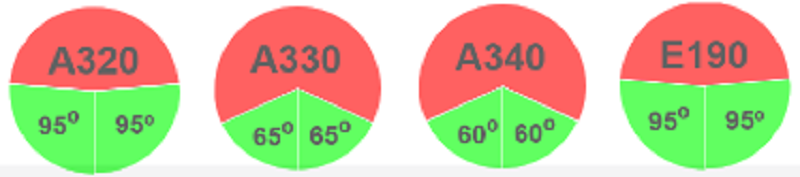

What do these symbols represent, with respect to aircraft towing?

Max towing angle for the nose landing gear.

The max temperature for the nose landing gear shock strut.

Max towing angle for the main landing gear.

The max steering angle for the tow tractor axle.

What is the aircraft towbar equipped with to prevent damage to the landing gear, if the stresses on the towbar are beyond safe operating limits.

The towbar is equipped with a high strength bolt to prevent the towbar from disengaging from the aircraft to prevent damage to the aircraft landing gear.

The towbar is equipped with a shear pin to prevent damage to the aircraft landing gear. It will shear if the stresses are too high on the towbar.

The towbar is equipped with explosive bolts the tractor operator can activate to prevent damage to the aircraft landing gear.

The towbar is equipped with an auto disconnect function to prevent damage to the aircraft landing gear.

When towing an aircraft it is necessary to put the nosewheel steering in bypass mode. How do we ensure the steering is in bypass?

Ensure the steering bypass pin is installed, or the nose landing gear torque links disconnected.

The force of the tractor and towbar are capable of overpowering the steering systems on all aircraft, therefore it is not necessary to deactivate the steering.

The aircraft steering is automatically in bypass mode when the aircraft is in ground mode.

Ensure the hydraulic systems are depressurized.

What 2 factors affect our safety when dealing with electricity and the use of GPU'S?

The 2 factors are, power requirements and overvoltage.

The 2 factors are, shock and respect.

The 2 factors are, horseplay and driving the tow tractor.

The 2 factors are, fear and overconfidence.

Some GPU'S, like the one we have at the school, has both AC & DC cables to suit a wide range of aircraft. How can you tell the two power sources apart?

The AC cable and the DC cable have different plugs on them.

The cart is only capable of generating one type of power either AC or DC, but not both.

There is no difference they are fully interchangeable for all aircraft types.

The carts are only available with a diesel engine to operate the GPU.

Can the air source that connects to the aircraft's ventilation system for heating or cooling be controlled by the aircraft systems, or is it pre-conditioned air?

�Air that is supplied to the aircraft ventilation duct is a fixed temperature on the supply unit, no adjustment is permitted.

Air supplied to the aircraft ventilation duct is only used for pressurization tests not for temperature control

�Air that is supplied to the aircraft ventilation duct is controlled by selecting heating or cooling on the aircraft systems onboard.

�Air that is supplied to the aircraft ventilation duct is controlled by selecting heating or cooling on the supply unit.

How would you lift a B777 in order to replace a main wheel?

By using the aircraft jacks to lift the entire airplane high enough to replace the main wheel.

By using a main landing gear axle jack to lift the main wheel high enough to replace it.

By using a nose landing gear jack to lift the main wheel high enough to replace it.

You can replace the main wheel without jacking any part of the aircraft.

When towing an aircraft, the aircraft braking system needs to be pressurized prior to towing. When do we use the aircraft braking system during a tow?

Aircraft brakes must never be applied during towing, except upon command by tow tractor operator in an emergency situation.

Aircraft brakes are only applied when the aircraft tow is going downhill.

Applying the aircraft brakes during the tow will depend on what the brakeman in the flight deck wants to do.

Aircraft brakes are normally used to stop the aircraft during all aspects of the tow operation.

When towing in a congested area such as into or out of the hangar, what is the best practice for the tractor positioning?

The position of the tractor doesn't matter when towing in a congested area.

The tractor should face the direction of travel, facing forward when towing the aircraft forward. Facing the aircraft when pushing the aircraft backwards.

The tractor should always face the aircraft.

The tractor should always face forward.

What is this hand signal?

Chocks removed

Chocks installed

Steering disconnected

Ground power removed

The CRJ towbar is connected to the aircraft to be able to tow it. Where do you connect it?

To the lower torque link attach fitting.

To the nose landing gear steering actuators.

To the upper torque link attach fitting

To the nose landing gear axle.

The direction that aircraft are to be parked and tied down is determined by?

By what ever the pilot in command decides.

The company operating the aircraft decides where to tie the aircraft down.

Prevailing or forecasted wind direction, will be the direction to tie the aircraft down.

The aircraft are seldom tied down.

On a helicopter with skids, what is the method of securing or tying the helicopter down?

Attaching ropes from the forward and aft cross tubes to the anchor points in the ground

Putting sandbags or weights on the skids

Tie a rope around the tail boom and secure it to the anchor point on the ground.

Attaching ropes from the rotor blades to the anchor points in the ground

Boom lifts are used by AME'S to access aircraft components. When an AME uses a boom lift a safety harness is required. Where does the AME attach the lanyard that connects the safety harness to the boom lift?

Anywhere on the top railing of the basket.

Anywhere on the middle railing of the basket.

An engineered or controlled anchor point only.

To the door of the basket only.

When parking a stair truck on a large aircraft it can be difficult to see when the stairs will contact the aircraft. How do we ensure the stairs are aligned correctly and at the proper height.

There are special crews on the airfield who are dedicated to installing and removing the stairs on the aircraft at the airport. Maintenance personnel are not permitted to operate the stairs.

Only experienced personnel are allowed to operate stair trucks as it takes a great deal of skill to align the stairs without damaging the aircraft.

The use of a second person is necessary to avoid damage to the aircraft and allow people to embark and disembark safely.

The airplanes are parked at the terminal where moveable bridges are installed on the aircraft. They are what's used to access the aircraft for both passengers and maintenance crews.

What is a necessary step to complete before driving a set of access stairs from one aircraft to another or to park the stairs in a designated parking spot?

The stairs must must be fully retracted prior to moving the stair vehicle.

The stairs must have the stabilizers deployed prior to moving the stair vehicle.

The stairs must be lifted to the halfway extended point prior to moving the stair vehicle.

The stairs must be fully extended prior to moving the stair vehicle.

What is printed in box 1 on a form 1

Block 1 is used to identify the approving Civil Aviation Authority

Block 1 is used by AMO's to certify the work performed on the aeronautical product identified

Block 1 is used to identify the part number of the associated item being released by the form 1

Block 1 is used for the form tracking number

What are the 2 major hydraulic fluid categories?

Mineral based such as, Mil-H-5606 & Phosphate esters like, Skydrol or HyJet

Mineral based such as, Mil-H-5606 & vegetable based fluids.

Phosphate esters like, Skydrol or HyJet & vegetable based fluids.

Polyalphaolefin-Based Fluids & vegetable based fluids.

1 of the more important things a fuel system must provide the flight crew is?

The total useable fuel quantity available in one tank.

The total useable fuel quantity available in all tanks.

The total useable fuel quantity available for the wing tank only.

The total useable fuel quantity available to the APU only.

What do we use this tool for?

Checking the tire pressures.

Checking for contamination like water in the fuel system.

Checking for skydrol in the fuel system

Checking the oil system for fuel

Are we permitted to fuel an aircraft inside the hangar?

Yes, but only if it is pressure refueling of a reciprocating engine aircraft.

Yes, but only if it is pressure refueling of a turbine engine aircraft.

Yes, but only if it is overwing refueling of a reciprocating engine aircraft.

No, all aircraft fueling procedures must be performed outside.

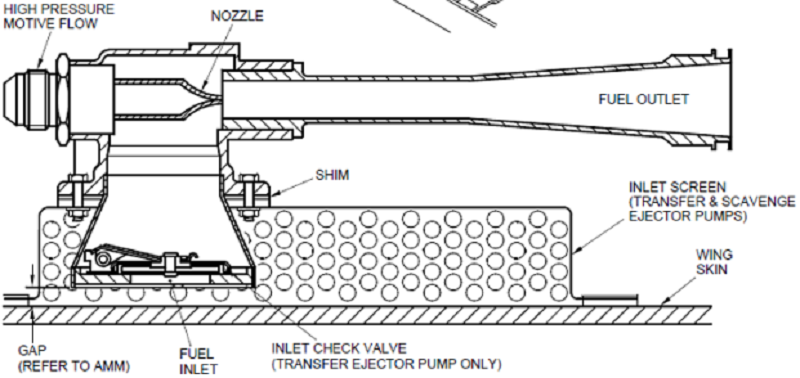

How do ejector pumps operate in a fuel system, like the CRJ fuel system?

Ejector pumps have their own internal low powered pump to supply the fuel it draws fuel from the tank through the ejector pump inlet to the fuel outlet in the ejector pump.

Ejector pumps are operated by fuel pressure. High pressure fuel supplied to the nozzle by the engine driven pump, which draws fuel from the tank through the ejector pump inlet to the fuel outlet in the ejector pump.

Ejector pumps are operated by fuel pressure. High pressure fuel supplied to the nozzle by the electric boost pump, draws fuel from the tank through the ejector pump inlet to the fuel outlet in the ejector pump.

Ejector pumps have their own internal high powered pump to supply the fuel it draws fuel from the tank through the ejector pump inlet to the fuel outlet in the ejector pump.

If the primary fuel quantity indicating system is inoperative, is there an alternate method to measure the fuel quantity?

Magnetic level measuring sticks may be used to manually check the level of fuel in the tanks.

Opening the over wing fuel cap and observing the level of fuel inside the tank.

Interrogating the fuel system computer and the maintenance interrogation computer to find the fuel quantity.

Rely on the fuel truck readings to calculate the total fuel uploaded.

What is the primary purpose of the nitrogen generating system for fuel tanks?

The nitrogen enriched air (NEA) is used to decrease the fuel tank flammability.

The nitrogen enriched air (NEA) is used to decrease the fuel tank flammability of the centre tank only.

The nitrogen enriched air (NEA) is used to increase the fuel economy of the aircraft.

The nitrogen enriched air (NEA) is used to increase the volatility of the fuel.

The fuel jettison system like the one on the B787 is used to jettison or dump fuel overboard. Why would we dump fuel overboard?

The landing gear is inhibited if the aircraft has too much fuel onboard. We dump the fuel overboard to allow the landing gear to extend.

We dump fuel overboard to save the defueling charges the airport imposes on the owner of the aircraft.

We dump fuel overboard to decrease the landing weight of the aircraft.

We dump fuel overboard to increase the landing weight of the aircraft.

Does aircraft grease have a shelf life?

Yes it does, all greases have the same shelf life of 24 months.

No, as long as the container remains sealed it can be stored indefinitely.

Aircraft grease can be stored indefinitely as long as it is kept in a freezer at -12C or colder.

Yes, although it varies with the type of grease it should be clearly stated on the container.

What is the most common type of knot for tying down an aircraft?

A slip knot

Transom knot

A bowline knot

A highwayman knot

When fueling an aircraft safety is an important factor, how does the fueler reduce the risk of static electricity?

By ensuring the hose on the fuel truck is secured to the aircraft's fuel port tightly.

By making sure the fuel hose to the hydrant in the ground is secured tightly.

By using fuels that don't produce static electricity.

By ensuring the fuel truck is grounded, and bonded to the airplane.

Both the CRJ service door and the Citation main cabin door have a way of preventing the door from moving when it is fully opened. What is this commonly referred to as?

The doors are held in place by an over centre linkage.

There is a cam and latch mechanism that locks the doors open and must be released prior to closing the door. It is commonly referred to as a gust lock.

The weight of the doors themselves are what keep them open.

The doors are held open by a counterbalance weight that is attached by ground crew personnel after opening the doors.

If the door handle is left unlatched on the CRJ main cabin door, would the pilots be aware of this prior to take off?

No, they rely on the ground crew to close and lock all doors properly prior to departure.

Yes, there would be a flight deck indication telling them there is a door open.

No, only the avionics bay door has an indication in the flight deck.

No, only the cargo door has an indication in the flight deck.

What are the two factors that affect safety when dealing with electricity

These two factors are portable GPU'S and fixed base power units

These two factors are high voltage and frequency

These two factors are power cables being to short or too heavy

These two factors are Fear and overconfidence

When attaching conditioned air to an airplane from a portable air conditioning cart, what is the correct order to follow when connecting it?

Connect the hose to the airplane, start the unit, select heating or cooling, select the correct flow rate.

Start the unit, connect the hose and close the supply valve to the unit.

Start the unit, connect the hose to the airplane, select heating or cooling, set the flow rate to high.

Start the unit, select the airflow to high, select heating or cooling, then connect it to the airplane.

Does the Cessna Citation aircraft have 1 or 2 hydraulic reservoirs?

Only 1 reservoir for all hydraulically operated components.

Only 1 system for all hydraulically operated components.

2 systems for all hydraulically operated components that share the same reservoir.

2 reservoirs, 1 for the aircraft hydraulically operated components, and 1 for the braking system.

Do reciprocating engine powered aircraft and turbine powered aircraft use the same fuel?

No reciprocating engine powered aircraft use avgas and turbine powered aircraft use kerosene (jet fuel)

Yes there are different octane ratings but it essentially the same fuel.

Yes all aircraft use jet A-1 as a fuel source.

No, some aircraft use jet A-1in extreme cold and some use jet B in the warmer weather.

There are several different types of contamination of an aircraft fuel system, what is the most common type of contamination?

Incorrect fuel type for the aircraft or (mixing of fuels) is the most common type of contamination.

Solid particles and surfactants are the most common type of contamination.

Microorganisms are the most common type of contamination.

Water is the most common type of contamination.

What is considered the worst type of fuel system contamination?

Incorrect fuel type for the aircraft or (mixing of fuels) is the worst type of contamination.

Microorganisms in the fuel is the worst type of contamination.

Solid particles and surfactants are the worst type of contamination.

Water in the fuel is the worst type of contamination.

How would a pilot reduce the amount of fuel onboard the aircraft in an emergency?

The pilot would reduce the power lever angle to send the maximum amount of fuel through the engines to use as much fuel as possible.

The pilot would use the jettison system to dump the fuel overboard prior to landing.

The pilot would transfer all the fuel to the centre tank of the aircraft prior to landing.

The pilot would use the crossfeed valve to balance the fuel weight evenly to reduce the landing force on the main gear

When using the magnetic level indicators to check fuel quantity what do we have to check in order to get an accurate reading from each fuel tank?

The pitch and roll of the aircraft.

The hydraulic reservoir quantities.

The main gear tire pressures.

The main and nose gear tire pressures.

Is it ok to mix oil brands in turbine engines?

Yes, provided the oil manufacturer allows it. You must perform a complete oil changeover in the engine. Gradual change is not permitted.

Yes, provided the engine manufacturer allows it.You need to pay particular attention to method of changeover.

No. Not under any circumstances.

You need to perform a gradual changeover 1 litre at a time of 50 flight hours.

When checking the hydraulic fluid on the CRJ, does the temperature of the fluid make a difference to the reservoir quantity?

The temperature only affects the operation of the pumps not the fluid level.

Yes the reservoir has a different service level for the hot fluid, and for cold fluid temperature

The fluid temperature determines if it is necessary to use the hot or cold hydraulic fluid for reservoir servicing

No the reservoir is serviced the same way regardless of fluid temperature

When is it ok to mix oil brands in turbine engines?

You must perform to a complete oil changeover in the engine, regardless of manufacturer's method of changeover

When the engine manufacturer allows it. However, you need to pay particular attention to the method of changover

Not under any circumstances

You need to perform a gradual changeover 1 litre every 50 flight hours. Engine manufacturers don't provide instructions for oil changeover

When fueling an aircraft safety is an important factor, how does the fueler reduce the risk of static electricity?

By ensuring the hose on the fuel truck is secured to the aircraft's fuel port tightly..

By ensuring the fuel truck is grounded, and bonded to the airplane

By making sure the fuel hose to the hydrant in the ground is secured tightly

By using fuels that don't produce static electricity

If the primary fuel quantity indicating system is inoperative, is there an alternate method to measure the fuel quantity?

Rely on the fuel truck readings to calculate the total fuel uploaded

Magnetic level measuring sticks may be used to manually check the level of fuel in the tanks.

Interrogating the fuel system computer, and the maintenance interrogation computer to find the fuel quantity

Opening the over wing fuel cap and observing the level of fuel inside the tank

{"name":"Servicing Midterm", "url":"https://www.quiz-maker.com/QPREVIEW","txt":"How are the calibrated tools in stores are maintained in a serviceable condition?, Where would you find the PPE (personal protective equipment) requirements for using chemicals like, hydraulic fluid or acetone?, What is the difference between box 13 and box 14?","img":"https://www.quiz-maker.com/3012/CDN/101-4967670/service1.png?sz=1200"}

More Surveys

One to One

6316

Student Union

4228

College Heartbeat Leavers Survey

29140

The Coronavirus Vaccine Side Effects Poll for people with SS, autoimmune conditions and fibromyalgia

1160

How do certain foods effect your behaviour?

10542

Private member survey

5230

Fiona's password policy

5225

A short survey about the Philippines

7423